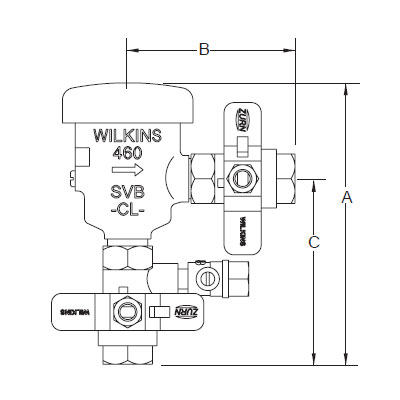

40 pressure vacuum breaker diagram

800M4QT. ×. Anti-Siphon Pressure Vacuum Breaker Backflow Preventers. Series 800M4QT Anti-Siphon Pressure Vacuum Breakers prevent the reverse flow of polluted water from entering into the potable water supply due to backsiphonage. They have a bronze body construction, silicone rubber check valve disc, plastic check valve seat, stainless steel ...

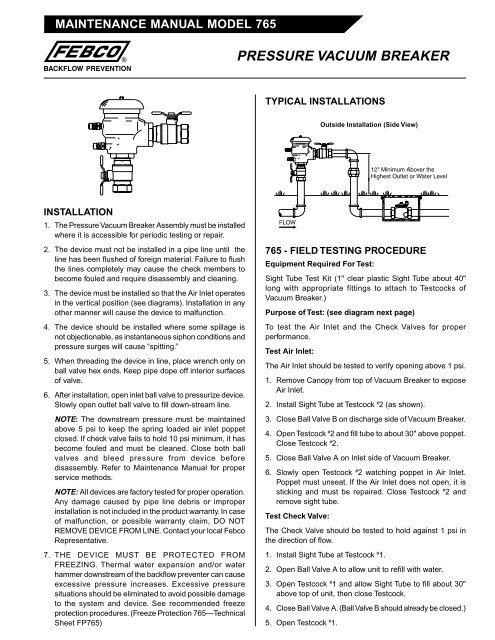

Vacuum Breaker.) Purpose of Test: (see diagram next page) To test the Air Inlet and the Check Valves for proper performance. Test Air Inlet: The Air Inlet should be tested to verify opening above 1 psi. 1. Remove Canopy from top of Vacuum Breaker to expose Air Inlet. 2. Install Sight Tube at Testcock #2 (as shown). 3.

11 Sept 2020 — English: If the pressure in the water system happens to drop, the poppet valve drops as well, to compensate for the loss of pressure, and so the ...

Pressure vacuum breaker diagram

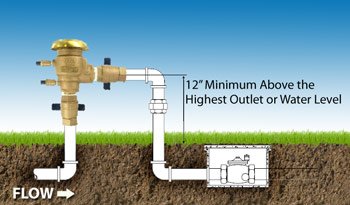

When unwanted vacuum conditions occur at the higher elevation points it is possible that a vacuum breaker may be introduced in to the system. In Pipe Flow Expert the vaccum breaker can be modelled by using an End Pressure and a Demand In-Flow as is shown in the following diagram. Essentially the system is split in to two separate systems.

Is your pressure vacuum breaker leaking or malfunctioning? It may be in need of repair. The Watts - Ames experts walk you through this quick fix, including t...

A diagram of a Pressure Vacuum Breaker is illustrated below along with typical installation drawings: pvb pvbagricultural pressurevacuumbreaker.

Pressure vacuum breaker diagram.

If the pressure in the "upstream side" is reduced to atmospheric pressure or below, the poppet valve drops and allows air to enter the system, breaking the ...

Like Watts on Facebook at http://www.facebook.com/wattsbrandIs your pressure vacuum breaker leaking or malfunctioning? It may be in need of repair. The Watts...

Pressure Vacuum Breakers An anti-siphon pressure vacuum breaker shall be installed where indicated on the plans to prevent the back-siphonage of contaminated water. This assembly is not to be used where there is a possibility that a back pressure condition may devel-op. The assembly will incorporate an acetal bonnet with silicone

PRESSURE VACUUM BREAKER 765 – Field Testing Procedure Equipment Required For Test: Sight Tube Test Kit (1" clear plastic Sight Tube about 40" long with appro-priate fittings to attach to Testcocks of Vacuum Breaker.) Purpose of Test: (see diagram) To test the Air Inlet and the Check Valves for proper performance. Test Air Inlet: The Air Inlet ...

Vacuum Breaker Valve 720A has all Bronze Body and Bonnet Construction With a Maximum Water Pressure 150 Psi. An Ideal Choice for Industrial and Commercial ...30 Mar 2018 · Uploaded by Zurn Industries, LLC

A pressure vacuum breaker consists of a check device, or check valve, and an air inlet that is vented to the atmosphere (open-air). The check valve is designed to allow water through and keep the air inlet closed during normal conditions. When the air pressure is greater than the water pressure, the vented chamber opens and breaks the suction ...

Vacuum Breaker.) Purpose of Test: (see diagram next page) To test the Air Inlet and the Check Valves for proper performance. Test Air Inlet: The Air Inlet should be tested to verify opening above 1 psi. 1. Remove Canopy from top of Vacuum Breaker to expose Air Inlet. 2. Install Sight Tube at Testcock #2 (as shown). 3.

Before opening the pressure vacuum breaker assembly, close the isolation valve, the outlet shutoff valve, and the inlet shutoff valve in that order. Open test cock #2 to release pressure. Then remove the assembly cover. One common cause of pressure vacuum breaker malfunction is debris in the system, particularly the poppet or check assembly.

/Pressure-Vacuum-Breaker-58f127fa3df78cd3fc3c18e5.jpg)

0 Response to "40 pressure vacuum breaker diagram"

Post a Comment