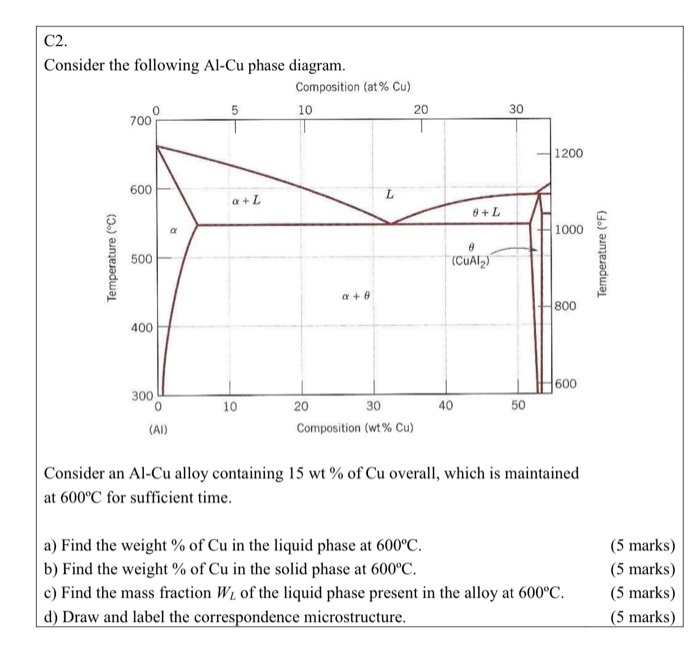

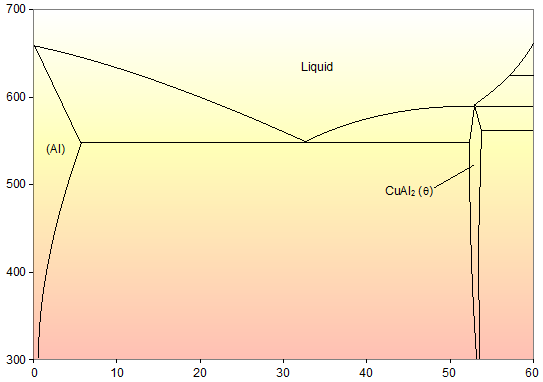

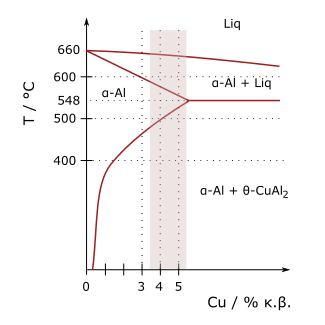

41 al-cu phase diagram

The NiNb 2 O 6 powder was synthesized by a simple calcination process following a phase diagram study of this material system in 2005. Niobium dioxide (99%, Alfa Aesar) and nickel oxide (99%, Sigma-Aldrich) powders in a molar ratio 1:1 were mixed for 24 h, and subsequently calcined at 1423K for 2 h. Material Characterization The fluorine salt system is a potential electrolyte for the preparation of metals and alloys from metal oxides via molten salt electrolysis. The solubility of ZrO 2 in KF-AlF 3 -Al 2 O 3 molten salts (KF/AlF 3 molar ratio = 2.1-2.8, Al 2 O 3 content = 0-9 wt.%) was measured using the isothermal saturation method in this study. The influence of temperature and electrolyte composition on ...

The complete phase diagram of Al-Si nanoalloy for 10-nm and 2-nm particle radii has been compared with the equilibrium phase diagram of the system in Fig. 6. It is noted that with the reduction of the particle size solidus, liquidus and eutectic line shift to lower temperature; in addition to this, due to reduction of particle diameter solid ...

Al-cu phase diagram

Phase Diagram Resources from ASM International. Alloy phase diagrams and crystal structure data are used by metallurgists, materials engineers, and materials scientists to develop new alloys for specific applications; fabricate these alloys into useful configurations; design and control heat treatment procedures for alloys that will produce the required mechanical, physical, and chemical ... Oct 05, 2010 · This repository provides a source for interatomic potentials (force fields), related files, and evaluation tools to help researchers obtain interatomic models and judge their quality and applicability. Users are encouraged to download and use interatomic potentials, with proper acknowledgement, and developers are welcome to contribute potentials for inclusion. Meanwhile, the 'quintuple-layer' compound R 6 Ni 5 O 12 (n = 5) with average d 8.8 (Ni 1.2+) filling falls directly at the optimal doping to align with the cuprate phase diagram and is thus an ...

Al-cu phase diagram. Extended Data Fig. 2 shows the HPHT phase diagram of C 60 from earlier studies and this study. High-quality sp3 amorphous carbon is only synthesized in a narrow pressure-temperature ( P - T ... Copper is a chemical element with the symbol Cu (from Latin: cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity.A freshly exposed surface of pure copper has a pinkish-orange color.Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling ... View and Download Carrier 48TM004-007 installation, start-up and service instructions manual online. Single-Package Rooftop Heating/Cooling Units. 48TM004-007 air conditioner pdf manual download. Also for: 48tf004-007. However, as per Al-Zn binary phase diagram, zinc-rich β phase which normally found segregated at the inter-dendritic α-Al phase of Galvalume ® coating containing 43 wt.% Zn (Ref 24,25,26) was not identified in the microstructure containing 10-11 wt.% Zn shown in Fig. 4. Few pores are also observed on the surface due to the solidification ...

Accordingly, NHC-Cu afforded a very large SV of up to 9.6 × 10 5 mL/g cat /h, which was one order of magnitude higher than those of current thermocatalysts (e.g., 3 × 10 3 mL/g cat /h for Cu 1 ... Revised to reflect recent developments in the field, Phase Transformation in Metals and Alloys, Fourth Edition, continues to be the most authoritative and approachable resource on the subject.It supplies a comprehensive overview of specific types of phase transformations, supplemented by practical case studies of engineering alloys. According to the Al-Cu phase diagram, after solution treatment at 538 °C, the Al 2 Cu phase will be in equilibrium with the matrix , meaning that the particles observed in fracture surfaces were coarse Al 2 Cu particles that exist in all specimens. However, for the alloy subjected to large pre-deformation, some coarse particles could be broken ... According to the analysis of equilibrium phase diagrams [41,42] (Figure 2d) of binary systems, the microstructure of the Al-Er master alloy should contain primary crystals of a solid solution of aluminum (Al) and eutectic [(Al) + Al 3 Er]. Eutectic with a high aluminum content contains about 6 wt.% Er and solidifies at 655 °C, which is ...

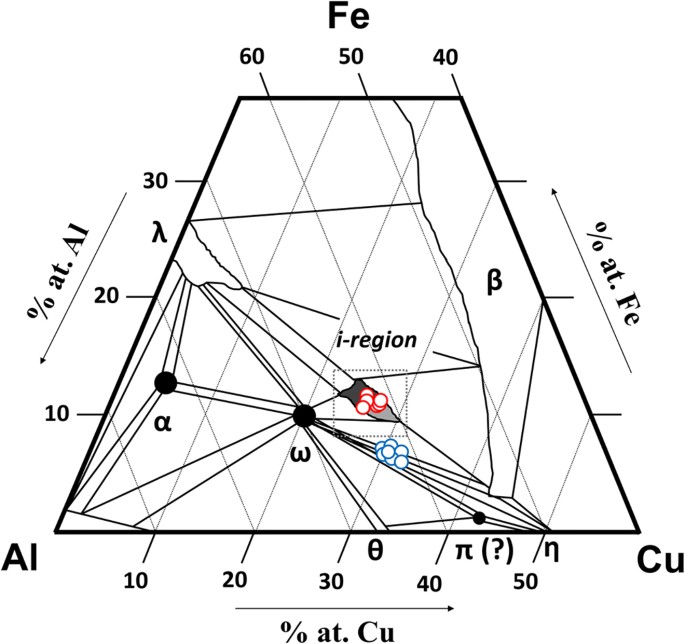

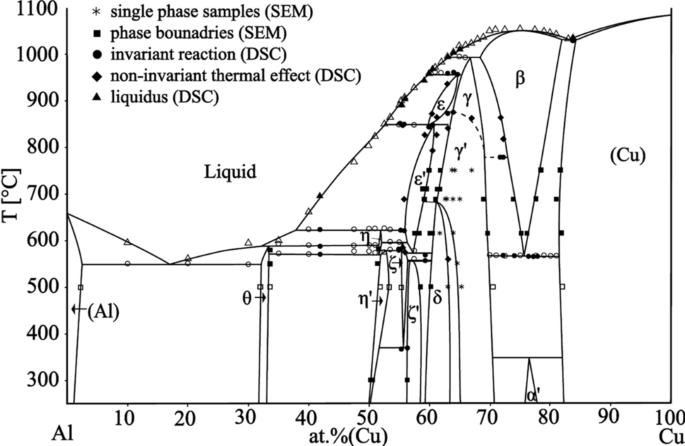

Phase equilibria and Heusler phase stability in the Cu-rich portion of the Cu-Al-Mn system Journal of Alloys and Compounds , 266 ( 1-2 ) ( 1998 ) , pp. 191 - 200 Article Download PDF View Record in Scopus Google Scholar In materials science, superplasticity is a state in which solid crystalline material is deformed well beyond its usual breaking point, usually over about 600% during tensile deformation. Such a state is usually achieved at high homologous temperature.Examples of superplastic materials are some fine-grained metals and ceramics. Other non-crystalline materials (amorphous) such as silica glass ... Reaction layers of II and III were also gray, but III contained some white phases. Based on the composition and Ti-Cu phase diagram, gray phases in II (Point C 1) and III (Point D 1) should be TiCu and Ti 3 Cu 4, respectively [, , ]. There were bulky white (Point E 1) and gray (Point F 1) phases in the center of brazing seam (IV). The thickness of the joint of Fig. 5b was obviously wider than that of Fig. 5a, which increased from 1 to about 2 µm.According to the binary phase diagrams of Al-Sn, Al-Zn and previous studies, the solubility of Al in Sn was very little, and the diffusion melting distance was very small. However, under secondary ultrasound, molten Al ...

Al-si phase diagram The combination of antibodies has been tested in phase 3 clinical trials (Baum et al., 2020b; Hansen et al., 2020). VIR-7831 (GSK 4182136), which has entered phase 2/3 clinical trials, is a fully human mAb, based on the S309 which is identified from a SARS survivor, that targets the RBD of SARS-CoV-2 and is developed by Vir ...

The EPMA analyses indicated that the chemical composition of the Mg-Sn intermetallic compound was Mg : Sn = 65.6 : 34.4 (at.%).According to Sn-Mg-Zn ternary phase diagram and the compositional analysis, the intermetallic compound corresponds to the Mg 2 Sn phase.The Pilling-Bedworth ratio of oxides preferentially formed from the precipitated phase s in magnesium alloys were cal cu lated.

Oct 05, 2010 · This repository provides a source for interatomic potentials (force fields), related files, and evaluation tools to help researchers obtain interatomic models and judge their quality and applicability. Users are encouraged to download and use interatomic potentials, with proper acknowledgement, and developers are welcome to contribute potentials for inclusion.

In addition to these, Wang et al. found a new ternary phase τ9 (Zr 29 Fe 29 Si 42) through detailed experiments , and Gabay et al. recently found a metastable hard magnetic phase ZrFe 10 Si 2 with a ThM 12 structure , . We refer to the latter phase as τ10 in this paper for convenience.

It also has stable cubic ErTe and Er 2 Te 3 phases in phase diagram. ... Song Z. T. et al. High endurance phase change memory chip implemented based on carbon-doped Ge2Sb2Te5 in 40 nm node for ...

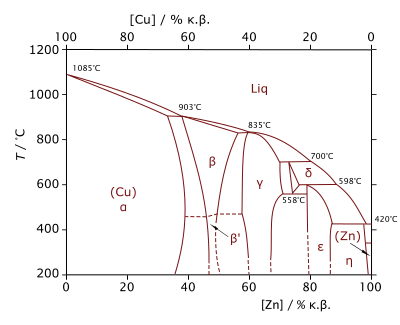

Among all the possible alloys of copper and zinc, brasses occupy a marginal role in the phase diagram. More precisely, copper alloys of technological interest have copper content ranging from 57% to 70%. The α phase has good cold workability while the β phase has good hot workability. CONTINUE

Red Pine Exploration Inc. announces it has engaged GoldSpot Discoveries to apply its proprietary machine learning technology and greenfield geoscience expertise on the Wawa Gold Project. GoldSpot ...

Aluminium alloys (or aluminum alloys; see spelling differences) are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc.There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable.

X-ray source: Cu Kα radiation. Peaks labeled with "*" are from the fluorine tin oxide (FTO) substrates. (B) Energy profile along the transition path between DMePDAPbI 4-1 and DMePDAPbI 4-2. (C) TRMC comparison of out-of-plane charge transport across the layers of n=1 2D perovskites.

Wu et al. have successfully performed the ultrasonic-assisted air soldering of SiC/SiC ceramic by using Sn-Zn-Al active solder. Koleňák et al. [12, 13] studied the direct bonding of Al 2 O 3 /Cu and silicon using Sn 2 La and Sn-Ag-Ti (Mg) solders, respectively. Their results demonstrated that adding active elements into the active solder can ...

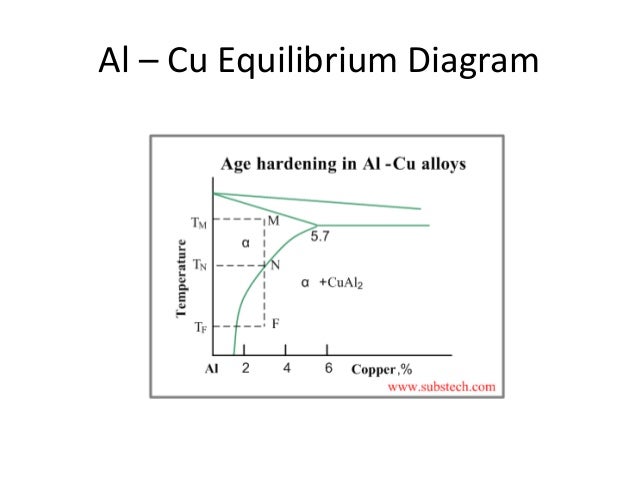

Strengthening mechanisms: Students will be able to understand how the Al-Cu phase diagram and manipulation by heat treatment can produce high strength aluminium-based alloys. They will be able to understand how the Fe-C phase diagram and manipulation by heat treatment can produce a range of steels relevant to engineering applications.

The solidification of AlCuSi alloys with Mn and Fe was studied by rotating a magnetic field to understand the effect of melt flow. The specimens solidified with a forced convection, low cooling rate and low temperature gradient. Electromagnetic stirring generated by an electric coil around the specimens caused a transformation from equiaxed dendritic to rosette morphology, occasionally with ...

To attain supersaturation, the catalyst temperature has to be in the Si(s) + L two-phase field of the Si-Cu binary phase diagram (Supplementary Fig. S2), on the condition that Si is supplied to ...

Revised to reflect recent developments in the field, Phase Transformation in Metals and Alloys, Fourth Edition, continues to be the most authoritative and approachable resource on the subject. It supplies a comprehensive overview of specific types of phase transformations, supplemented by practical case studies of engineering alloys. The book's unique presentation links a basic understanding ...

(A) Heating histories of Cu particles with different initial diameters. The inset is the Si concentration in the Cu droplets at the collection point. (B) Size distribution of the initial Cu particles and of the molten catalyst for DS mode.(C) Schematic representation of the mass transfer during nanorod growth, showing the Si redistribution at the growth interface (left) and the corresponding ...

The principal schematic and physical diagrams of EMPC for preparing Cu/CNTs compacts are shown in Fig. 3. EMPC technology was a high-speed forming technology. Specifically, electrical energy was converted into electromagnetic energy and then converted into mechanical energy [, , ]. The powders were quickly pressed into shape using mechanical ...

View Screenshot_20211124-201609_Office.jpg from STEM 301 at STI College (multiple campuses). Session #35: Homework Problems Problem # 1 (a) For each of the following Ag-Cu alloys state all phases

Neutral or Neutral Conductor—Includes the neutral conductor of a three-phase four-wire system, ... 3.0.1 Diagram. A diagram may show the manner in which the various parts of a network, installation, group of apparatus or items of an apparatus are interrelated and or interconnected. ... Al Cu: 10 16 4: iii)

Meanwhile, the 'quintuple-layer' compound R 6 Ni 5 O 12 (n = 5) with average d 8.8 (Ni 1.2+) filling falls directly at the optimal doping to align with the cuprate phase diagram and is thus an ...

Oct 05, 2010 · This repository provides a source for interatomic potentials (force fields), related files, and evaluation tools to help researchers obtain interatomic models and judge their quality and applicability. Users are encouraged to download and use interatomic potentials, with proper acknowledgement, and developers are welcome to contribute potentials for inclusion.

Phase Diagram Resources from ASM International. Alloy phase diagrams and crystal structure data are used by metallurgists, materials engineers, and materials scientists to develop new alloys for specific applications; fabricate these alloys into useful configurations; design and control heat treatment procedures for alloys that will produce the required mechanical, physical, and chemical ...

0 Response to "41 al-cu phase diagram"

Post a Comment