45 propane fuel system diagram

Propane responds to rich fuel mixtures opposite to gasoline. Full-throttle rich mixtures in gasoline engines allow atomized liquid gasoline to evaporate in the combustion chamber. Because propane is already vaporized before it reaches the combustion chamber, there is no way for it to provide internal cooling from the latent heat of evaporation. propane technicians performing field installation, operation and maintenance work. The Handbook has been written in a very straightforward and easy to understand format, with simple tables, diagrams and pictures to help guide service technicians through the process of installing and maintaining a propane gas system.

The system must then be wired into the car's electrical system, allowing for a functioning fuel gauge, as well as proper automatic switching between propane and gasoline (along with a dashboard-mounted manual switch). There must be connections to the car's ECU so that the engine controller can adjust for different fuel settings.

Propane fuel system diagram

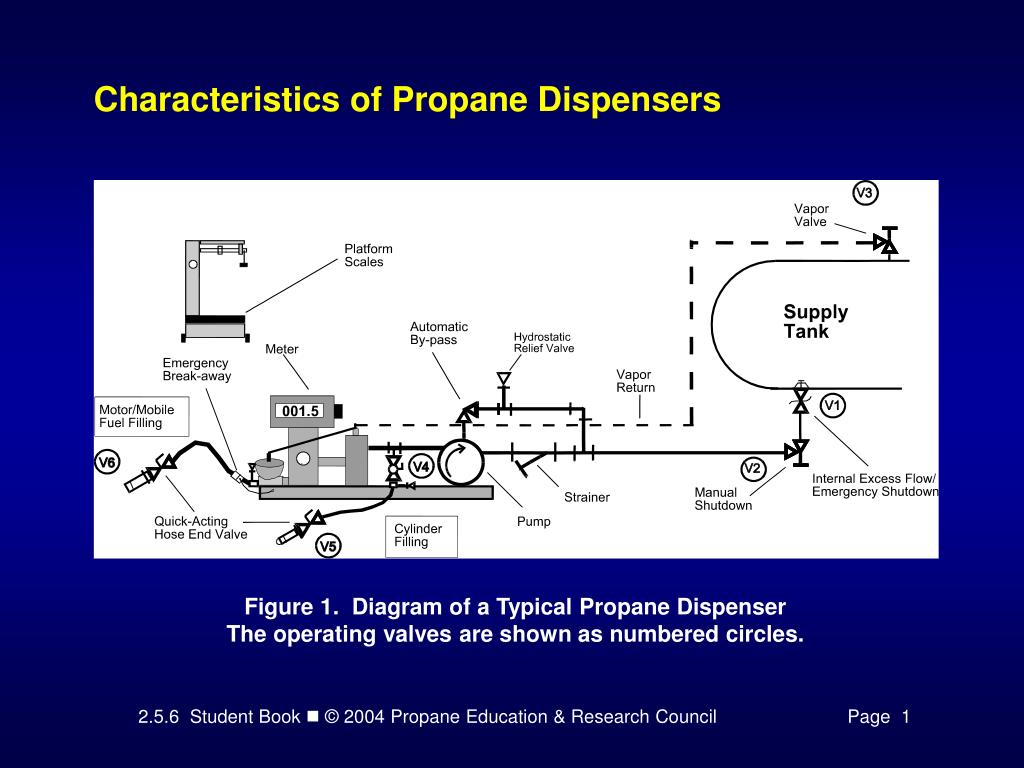

Implementing propane fuel for any of these applications requires a specialized understanding LPG system design that takes into consideration the nature of vaporization itself which is inherent to LPG fuel usage along with its myriad of related variables including LPG boil-off rate, ambient storage temperature, the size and fill level of the LPG ... propane is 15.5:1. With rich burn there is slightly less air delivered relative to fuel resulting in slightly less fuel efficiency, more power and a cooler combustion process. Figure 1 shows the required 4G engine control system configurations for Propane (VPG), Natural Gas (NG) and Bi-Fuel (VPG and NG) with the TWC. The LPEFI system is a sequential multi-port fuel injection system that injects propane in a liquid state to the engine. It works much the same way as a modern sequential multi-port gasoline fuel injection system and can be diagnosed with the same diagnostic scanners used for gasoline vehicles.

Propane fuel system diagram. Jun 23, 2021 · Only trained, qualified, and authorized individuals should perform maintenance on propane fuel systems. Propane can be as cold as -44° F and will cause serious injury if it comes in contact with your skin. Additionally, propane can leak from the fuel system and accumulate on the floor, presenting a fire or explosion hazard. Check the propane tank hooked up to the vaporizer to verify you have an adequate supply of propane. The vaporizer motor can be potentially damaged if it runs with an empty propane tank. Check that the valve is open as well so that the system receives gas. Inspect the system for signs of leaking. LPG FUEL SYSTEM TROUBLE DIAGNOSIS LPG FUEL SYSTEM TROU-BLE DIAGNOSIS Condition Cause Action Fuel leakage Looseness of piping connection Tighten Operating malfunction of vaporizer Repair, adjust or replace Poor connection or some foreign object is caught in between plunger rubber seat and valve seat of solenoid valve Clean, rub or replace Engine Will Not Start On Propane (Basic Troubleshooting) 1.) The first and most important step is to make sure that you are using a propane tank that has been refilled multiple times. (at least 4 times.) Tanks that have not been filled multiple times. will have air trapped inside of them causing the fuel mixture in the carburetor to be too lean.

The ZEEMS System The ZEEMS system is a "Speed-Density" design. This system measures the engine RPM (speed of the engine) and calculates the Density of the Air (from atmospheric pressure and temperature of the air) to determine the optimum fuel and air settings for the altitude and climatic conditions. or fuel system, and may influence the terms of the warranty. SECTION I INTRODUCTION Your new Powertrain Integration 8.0L engine has been designed and built to operate on Liquefied Pe-troleum Gas (LPG), commonly referred to as propane or autogas. Propane fuel is readily available and, when used as an engine fuel, provides a reduction in The ROUSH CleanTech liquid propane autogas fuel system features a return fuel system. The return line contains a flow control solenoid, either as a single component (as shown in Figure 1), or incorporated in a multi-function Fuel Rail Pressure Control Module, as shown in Figure 3 (FRPCM). The flow control solenoid is used by the Powertrain Control Module (PCM) to control fuel pressure in the fuel rail in order to ensure there is liquid propane in the fuel rail. Carburetion & Turbo Systems, Inc. Alternative Fuel Systems Specialists / CNG & Propane 1897 Eagle Creek Boulevard Shakopee, MN 55379 Tel: (952) 445-3910 / Fax: (952) 445-6070 Internet Website: www.CarbTurbo.com Page | 9 Two Ways To Convert Gasoline Engines To Gaseous Fuels There are two ways to convert gasoline engines to gaseous fuels.

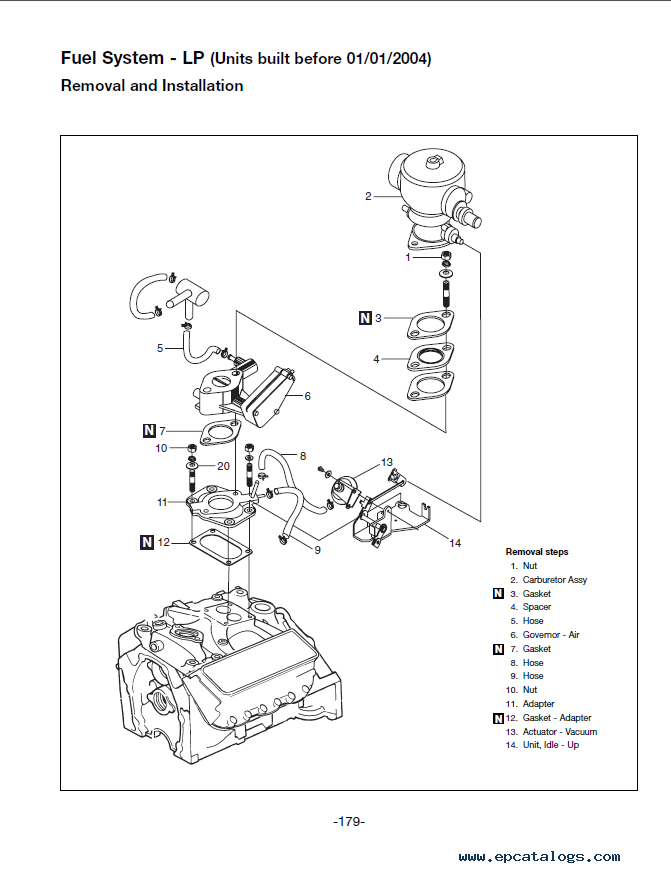

There are several components that need to be working together in order for the fuel system to work properly. First you have the fuel supply, the tank. Then there will be a fuel filter. To change the fuel filter, disconnect the fuel tank and discharge the line pressure by pressing in on the center pin of the hose fitting. Prins Autogassystemen B.V., part of Westport Fuel Systems, has been a pioneer in fuel system development of LPG, CNG and LNG fuel systems, for more than 35 years. We offer our customers high quality, cost-effective and innovative solutions for a wide variety of engine types. Typical LPG Fuel System (Items highlighted in boldface blueare shown on the diagram) Vacuum Fuelock Filter The Streamline carburetion system starts with the vacuum fuelock filter (VFF). When a slight vacuum signal from the engine (2" of water column [W.C].) is sensed by the VFF, the fuel is allowed to flow through a ten- alternative fuel and dissipates quickly when released into the atmosphere, propane vapor is heavier than air and seeks the lowest point. When the ratio of propane to air is between 2.2% and 9.6%, propane will burn in the presence of an ignition source at 940°F (504°C) or hotter. Keep away from heat, sparks, flames, static electricity or other

Fixing the propane system on the C70 Chevy with a fertilizer spreader on it.

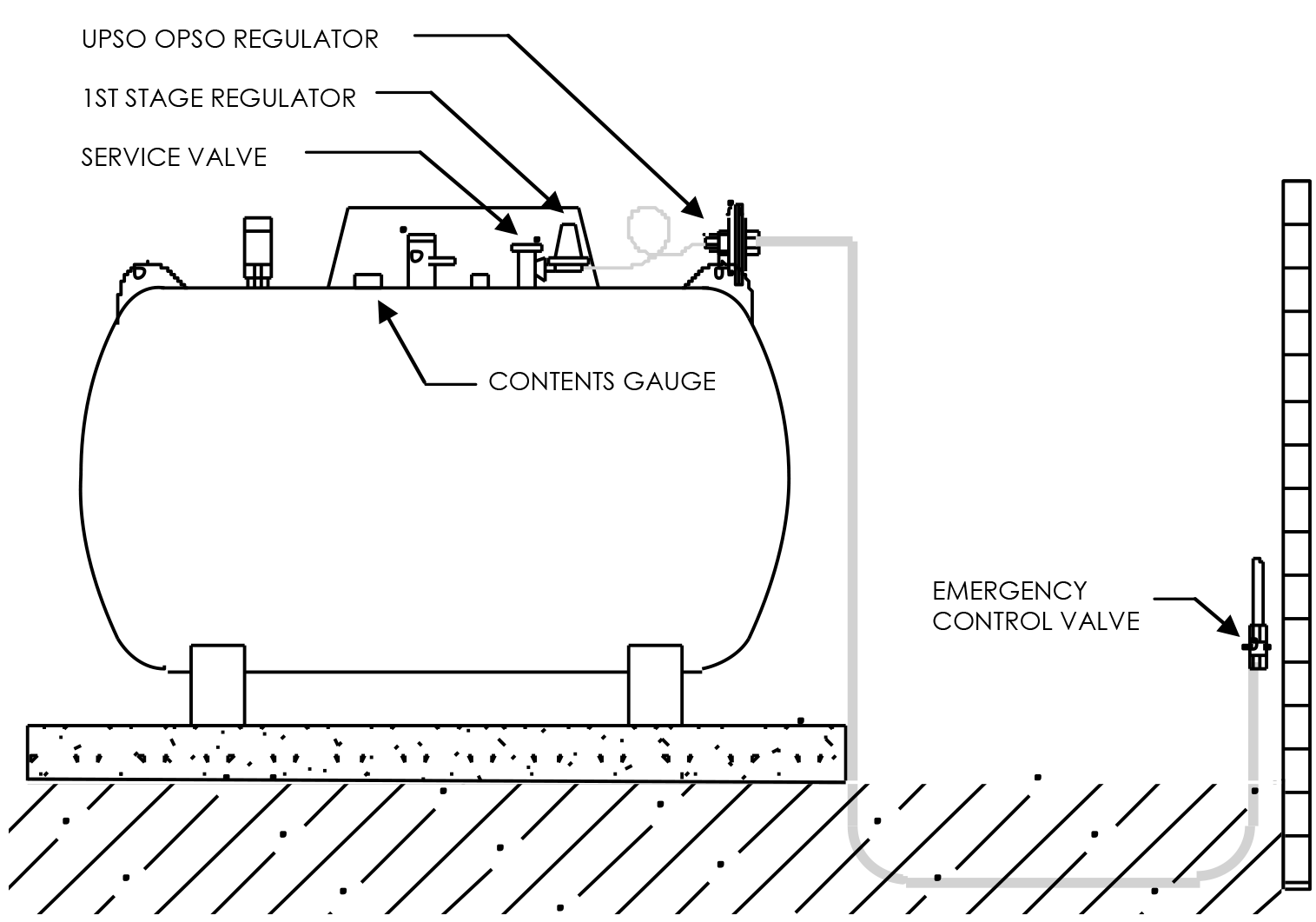

The Propane Technical Pocket Guide provides general information on how to prepare for the installation of propane systems for residential and commercial consumers. It includes key data and answers important questions relevant to construction professionals planning to incorporate propane in their construction projects.

Zenith Fuel Systems, Inc. has been manufacturing high quality gasoline and LPG fuel systems for industrial, military, agricultural and aircraft engines sine 1911. It is with this rich history that in 1993 Zenith foresaw that the need would arise for a more ac-curate and better performing fuel system and commenced the

Using the Propane Leak Detector tool (D540), check all fuel system fittings and fuel injectors for propane autogas leaks. If the Propane Leak Detector tool determines there is a leak, use a soap-and-water mixture to find the exact location of the leak. Repair any leaks before continuing.

Before working on any fuel system or engine, turn OFF the fuel system supply valve and .. NOTE: Wiring diagram attached at the end of this manual. 5) Lay the. LPG system wiring schematic vapouriser and impco gas carby, i dont have a priming system on this thing Impco Start Assist Valve. An overview of the LPG fuel system and its components.

How LPG works in an engine is fundamentally the same as a petrol powered internal combustion engine. The engine block, pistons, spark plugs, ignition system, lubrication system and electricals all work the same on LPG fuel, consisting of propane, butane or a blend of the two and are also referred to as natural gas liquids - NGL.

Fuel System Overview The PSI 8.8 liter LPG Engine's fuel system is composed of the fuel tank, Liquid Propane Delivery Module, fuel lines, fuel rails, and fuel injectors. The PSI 8.8 liter LPG engine utilizes a dual-cylinder liquid propane fuel tank. The primary cylinder contains the Liquid Propane Delivery Module's components. A certification label

Maybe a propane fuel systems sales specialist would have an idea. Purposely or knowingly defeating or disabling any part or the fuel and emission system may be in violation of the anti-tampering. Apr 8 2020 - forklift propane fuel system diagram - Google Search. 8-apr-2020 - forklift propane fuel system diagram - Google Search.

IMPCO® PROPANE FUEL SYSTEM 1998 GM Medium Duty Chassis Service Manual Supplement - Page 1 2/23/98 VEHICLE APPLICATION This IMPCO® propane system was designed to be installed on 1994 to1998 GM Medium Duty Chassis (>14,000 GVWR) with 6.0L and 7.0L V8.

Dec 01, 2020 · Diagram 97 Honda Fuel System Wiring Diagram Full Version Hd Quality Wiring Diagram Sitexeva Vmagazine It. Market drivers propanes preference as a forklift fuel is built upon the benefits propane offers to industrial forklift operators, including durable engine fuel systems for widely varying engine speed applications, lower carbon monoxide emissions, lower engine maintenance costs and ease of refueling.

the fuel and emission control system you should follow all the recommended service and repair procedures to insure the fuel and emissions system is operat-ing as designed and certified. Purposely or knowingly defeating or disabling any part or the fuel and emission system may be in violation of the anti-tampering

The LPEFI system is a sequential multi-port fuel injection system that injects propane in a liquid state to the engine. It works much the same way as a modern sequential multi-port gasoline fuel injection system and can be diagnosed with the same diagnostic scanners used for gasoline vehicles.

propane is 15.5:1. With rich burn there is slightly less air delivered relative to fuel resulting in slightly less fuel efficiency, more power and a cooler combustion process. Figure 1 shows the required 4G engine control system configurations for Propane (VPG), Natural Gas (NG) and Bi-Fuel (VPG and NG) with the TWC.

Implementing propane fuel for any of these applications requires a specialized understanding LPG system design that takes into consideration the nature of vaporization itself which is inherent to LPG fuel usage along with its myriad of related variables including LPG boil-off rate, ambient storage temperature, the size and fill level of the LPG ...

0 Response to "45 propane fuel system diagram"

Post a Comment